2025 Top Metal Detectable Cable Ties for Safety and Compliance in Industries

In industries where safety and compliance are paramount, the choice of materials used in everyday tools like cable ties can make a significant difference. Metal detectable cable ties are increasingly becoming essential for ensuring that manufacturing processes remain contamination-free, particularly in sectors such as food processing, pharmaceuticals, and packaging. According to the Food Safety Modernization Act (FSMA), businesses must adopt preventive controls and safety measures to minimize risks, with metal detection systems playing a critical role in safeguarding product integrity.

The growth of the global metal detectable products market, projected to reach USD 500 million by 2025, underscores the rising demand for these innovative solutions. Metal detectable cable ties not only enhance operational safety by enabling quick identification in case of contamination but also help organizations comply with stringent industry regulations, thereby mitigating the financial repercussions of non-compliance. As companies strive to maintain high standards of cleanliness and safety, the adoption of metal detectable cable ties will continue to rise, offering an effective means to meet both regulatory requirements and consumer safety expectations.

Overview of Metal Detectable Cable Ties

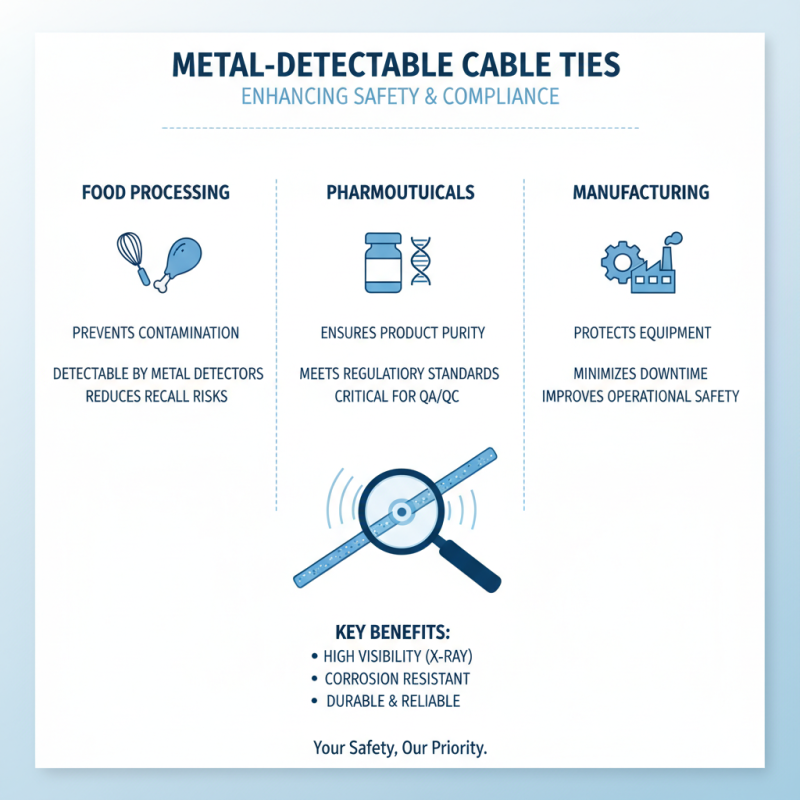

Metal detectable cable ties have become essential components in various industries, particularly in food processing, pharmaceuticals, and manufacturing, where strict safety and compliance standards are paramount. These cable ties are designed with specialized materials that allow for easy detection by metal detection systems, ensuring that any accidental breakage or loss within the production environment can be quickly identified and recovered. This capability significantly reduces the risk of contamination and enhances product safety.

In addition to their safety benefits, metal detectable cable ties play a crucial role in maintaining compliance with industry regulations. Many sectors are subject to rigorous quality control measures that require the elimination of foreign materials in the production line. By incorporating metal detectable cable ties, companies not only adhere to these standards but also promote a culture of safety and accountability within their operations. The visibility of these ties during inspections facilitates streamlined processes, minimizing disruptions and ensuring that operational standards are consistently met.

The Importance of Safety and Compliance in Industrial Environments

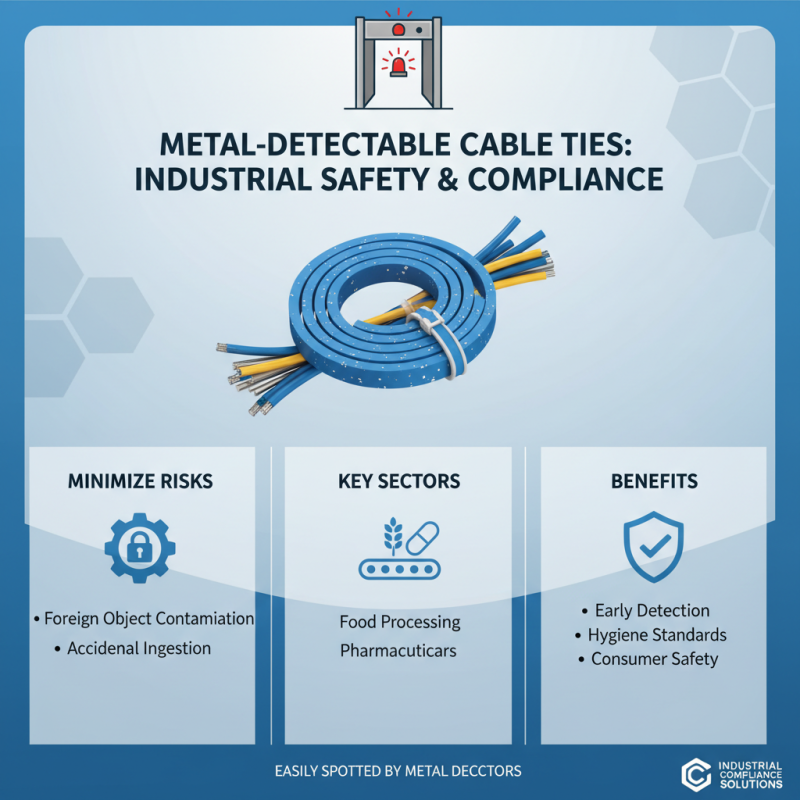

In industrial environments, ensuring safety and compliance is paramount. Metal detectable cable ties play a crucial role in minimizing risks associated with foreign object contamination, particularly in sectors such as food processing and pharmaceuticals. These specialized cable ties are designed to be easily spotted by metal detectors, thereby preventing accidental ingestion of foreign materials. By implementing such safety measures, industries can uphold strict hygiene standards and protect the health of their consumers.

Furthermore, adherence to safety regulations not only fosters a culture of compliance but also enhances operational efficiency. When companies prioritize safety by integrating detectable solutions, they reduce the likelihood of costly recalls and maintain their reputation in the market. Regular training and awareness programs about the importance of using compliant materials, such as metal detectable cable ties, empower employees to stay vigilant and proactive in maintaining safety protocols. Ultimately, a strong commitment to safety and compliance reflects a company's dedication to quality and consumer trust, driving long-term success in today's competitive industrial landscape.

Key Features to Look for in Metal Detectable Cable Ties

When selecting metal detectable cable ties for industrial applications, there are several key features that ensure safety and compliance.

First and foremost, the material composition is crucial.

These ties should be made from high-quality plastics that are integrated with metal powder, enabling them to be detected by standard metal detection equipment.

This characteristic significantly minimizes the risk of contamination in food processing and pharmaceutical industries,

where even the smallest foreign object can lead to severe safety violations.

Another important factor to consider is the tensile strength and durability of the cable ties.

They must withstand various environmental conditions, including extreme temperatures and exposure to chemicals.

Look for ties that offer high tensile strength ratings and resistance to UV light,

as these will ensure long-lasting performance in demanding settings.

Additionally, intuitive design features such as easy-to-use locking mechanisms can enhance efficiency while maintaining compliance with safety standards.

By prioritizing these features, industries can effectively implement metal detectable cable ties,

safeguarding both product integrity and consumer safety.

Top Brands Offering Metal Detectable Cable Ties in 2025

As industries increasingly prioritize safety and compliance, metal detectable cable ties have emerged as essential tools in various operational environments. These ties are specifically designed to be easily identified by metal detection systems, making them invaluable in settings such as food processing, pharmaceuticals, and electronics manufacturing. Leading manufacturers have recognized the growing demand and are focused on innovating their products to enhance detectability without compromising strength or versatility.

In 2025, several brands have established a strong reputation for providing high-quality metal detectable cable ties that meet stringent industry standards. Their products are made from advanced materials that not only allow for effective detection but also offer resistance to various environmental factors, ensuring durability. These brands emphasize the importance of compliance with health and safety regulations, providing customers with peace of mind that they are minimizing the risk of foreign object contamination while maintaining operational efficiency.

Applications and Benefits of Metal Detectable Cable Ties Across Industries

Metal detectable cable ties are becoming essential tools in various industries, particularly those where safety and compliance are paramount. These ties are engineered to be easily identified by metal detection systems, making them ideal for settings in food processing, pharmaceuticals, and manufacturing, where product contamination is a significant concern. By incorporating metal detection capabilities into cable ties, industries can enhance their quality control measures and ensure that any foreign objects are quickly identified and removed from production lines, minimizing the risk of accidents and costly recalls.

The applications of metal detectable cable ties span a wide range of uses, from securing equipment and bundling cables to organizing and categorizing materials in warehouses. Their robust design not only ensures that they withstand harsh environments but also guarantees visibility when scanned. This makes them an invaluable asset in maintaining a well-regulated workspace. Additionally, these ties offer benefits like durability, resistance to harsh chemicals, and compliance with stringent health and safety regulations, thereby promoting a safer working environment while improving operational efficiency. As industries increasingly prioritize safety and compliance, the adoption of metal detectable cable ties will likely become the standard procedure across various sectors.

Related Posts

-

The Ultimate Guide to Choosing Bulk Cable Ties for Every Project

-

Unlocking the Power of Small Zip Ties: Top 5 Insanely Useful Applications You Never Knew About

-

How to Choose the Right Plastic Ties for Maximum Strength and Durability

-

Exploring the Future of Bulk Zip Ties at the 2025 China Import and Export Fair

-

Innovative Zip Tie Tool Solutions Unveiled at the 2025 China Import and Export Fair

-

Top Benefits of Using Metal Cable Ties for Your Organization Needs