15 Essential Tips for Using Stainless Cable Ties Effectively

When it comes to organizing, securing, and maintaining a tidy space, stainless cable ties are an invaluable tool that often goes overlooked. These versatile fasteners are made from high-quality stainless steel, ensuring durability and resistance to corrosion, making them an ideal choice for both indoor and outdoor applications. From managing cables and wires to bundling various materials securely, stainless cable ties offer a reliable solution for a myriad of tasks. However, to maximize their effectiveness and ensure safety in use, certain techniques and tips should be adhered to. This article provides 15 essential tips for using stainless cable ties effectively, empowering you to harness their full potential in organizing your environment while ensuring longevity and performance. Whether you are a DIY enthusiast, a professional installer, or just someone looking to declutter, understanding the proper use of stainless cable ties can transform your approach to fastening and binding.

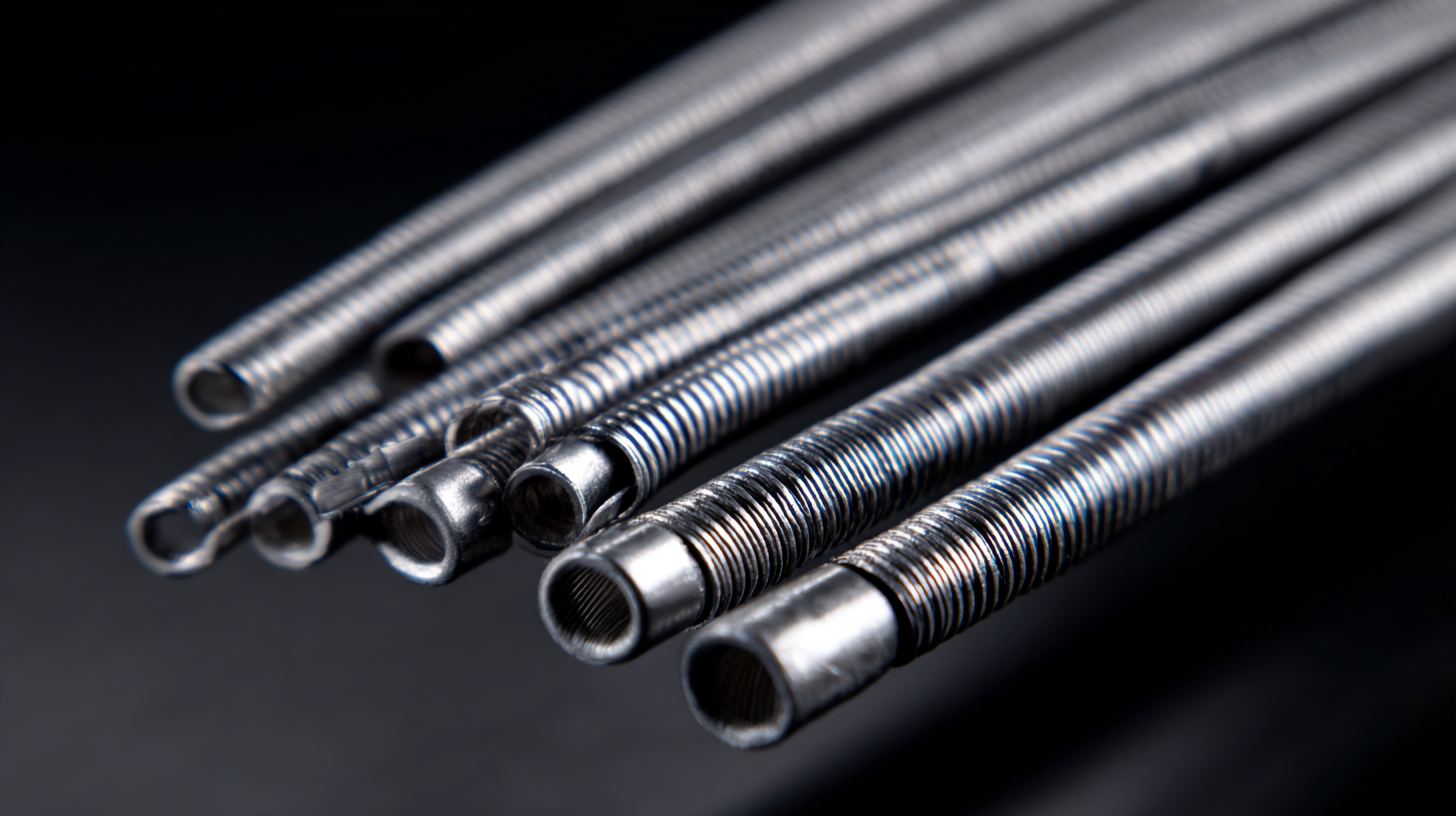

Understanding the Unique Properties of Stainless Steel Cable Ties

Stainless steel cable ties are renowned for their exceptional strength and durability, making them a preferred choice in various industrial and harsh environments. The unique properties of stainless steel, such as its resistance to corrosion and extreme temperatures, contribute significantly to the longevity of these cable ties. Unlike nylon ties, which can degrade over time due to UV exposure or moisture, stainless steel ties maintain their integrity, ensuring secure bundling of wires and cables in critical applications.

Another noteworthy characteristic of stainless steel cable ties is their ability to withstand mechanical stress. This resilience makes them ideal for situations where traditional ties may fail, such as in heavy machinery or outdoor settings exposed to varying weather conditions. Moreover, the high tensile strength of stainless steel allows for tighter and more reliable fastening, which is essential in maintaining the performance and safety of electrical systems. Understanding these unique properties empowers users to select the appropriate cable tie for their specific needs, optimizing both functionality and efficiency in their projects.

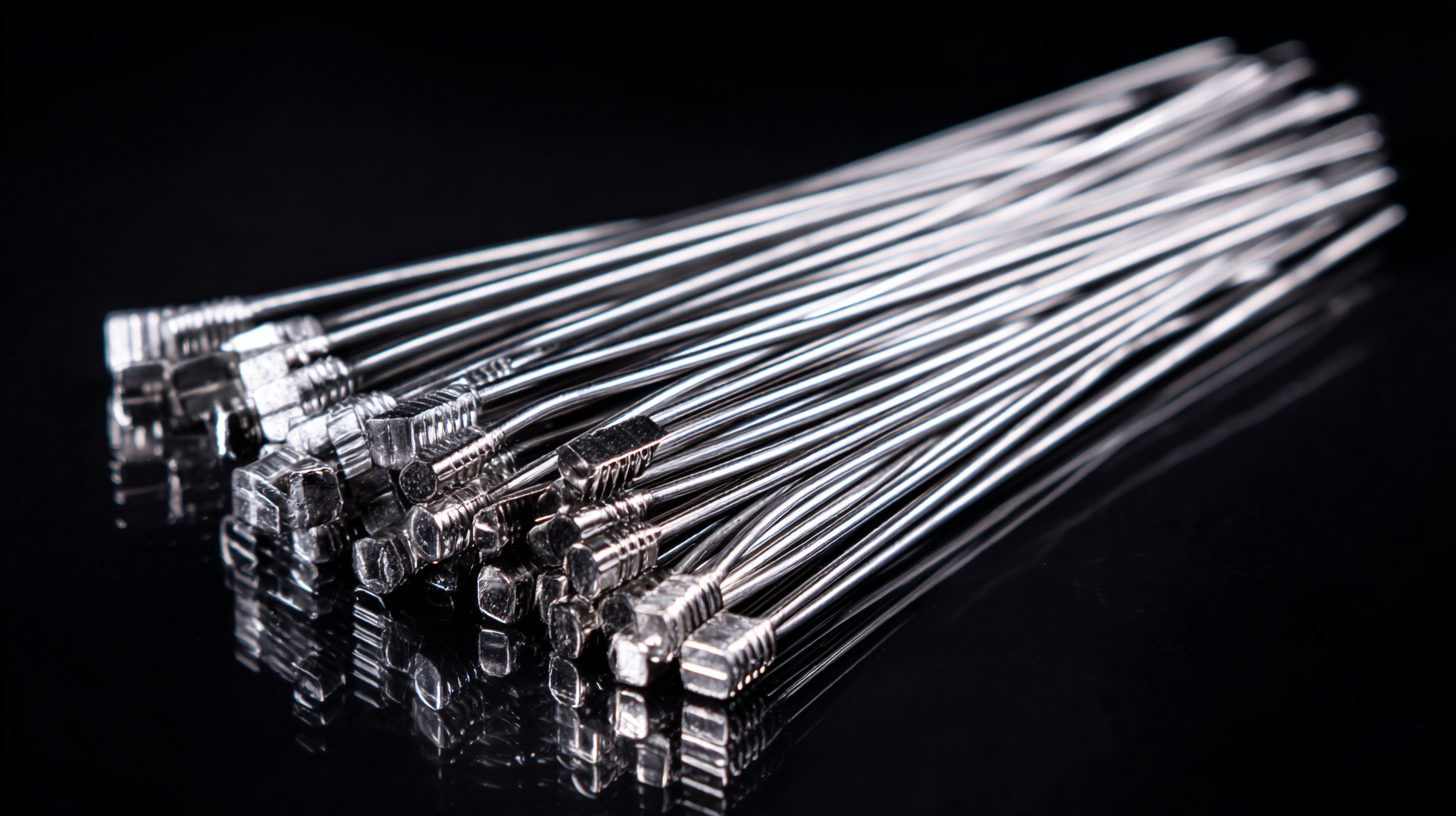

Choosing the Right Size and Type of Stainless Cable Tie for Your Project

When selecting stainless cable ties for your project, the importance of choosing the right size and type cannot be overstated. According to industry research, improper sizing can lead to significant structural issues, compromising the integrity of installations. Manufacturers recommend measuring the diameter of the bundle to be tied and adding a few millimeters to select a tie that will secure without excess tightness, which could damage the materials. For instance, a cable tie that is too small may not hold the desired strength, leading to failure under load conditions.

Additionally, the type of stainless cable tie plays a crucial role in achieving optimal performance. Various types are designed to withstand different environmental conditions, such as exposure to moisture or extreme temperatures. Reports indicate that ties made from marine-grade stainless steel offer superior resistance to corrosion, making them ideal for outdoor or maritime applications. Incorporating techniques from other industries, such as using specific fastening methods like sleeper techniques, can enhance the performance of cable ties in structural projects, ensuring they can handle uplift and lateral loads effectively.

15 Essential Tips for Using Stainless Cable Ties Effectively

Techniques for Properly Securing and Arranging Cables with Stainless Ties

When it comes to securing and arranging cables effectively, stainless cable ties offer a robust and durable solution. One essential technique is to ensure the right tension when fastening the ties. Over-tightening can damage the cables, while too loose a fit can lead to slippage. To achieve the perfect balance, always pull the cable tie snugly without excessive force, allowing for a bit of flexibility in the cables.

Another tip for efficient cable management is organizing cables by function or type. Grouping similar cables together not only enhances the aesthetic appeal but also simplifies future maintenance. Use color-coded ties to distinguish between various categories, making it easy to identify specific cables at a glance. This practice not only improves organization but also minimizes the risk of accidental disconnections or damage during maintenance tasks.

Lastly, always consider the environment where the cables will be used. Ensure that the stainless cable ties are suitable for outdoor or high-temperature applications if necessary. Using the right type of tie helps maintain the integrity of the cables and ensures long-lasting performance, making your cable management efforts more effective.

Best Practices for Maintaining and Storing Stainless Steel Cable Ties

When it comes to maintaining stainless steel cable ties, proper storage is essential for ensuring their longevity and effectiveness. Store them in a cool, dry environment to prevent exposure to moisture and humidity, which can lead to corrosion. Utilize sealed containers or bags to protect the ties from dust and debris, which can compromise their integrity. Keeping the ties organized not only saves time but also prevents misplacement, making it easier to access the right size when needed.

In addition to storage, regular inspection of stainless steel cable ties is crucial. Before use, check for signs of wear, rust, or damage. If a tie appears compromised, it's best to replace it to avoid potential failure in crucial applications. Cleaning the ties occasionally can also help maintain their appearance and performance. Using a soft cloth and a mild detergent can remove any building grime without scratching the surface. By following these best practices, users can ensure that their stainless steel cable ties remain reliable tools for various applications.

Safety Considerations When Using Stainless Cable Ties in Different Environments

When using stainless cable ties in various environments, safety considerations are paramount to ensure effective application and minimize risks. In harsh environments such as marine or industrial settings, it's important to choose cable ties specifically designed to withstand corrosion and extreme temperatures. These conditions can weaken standard cable ties, leading to potential failures that pose safety hazards. Always verify the specifications of the ties and ensure they are suitable for the specific environment in which they will be used.

Additionally, proper installation techniques are crucial to maintain safety while using stainless cable ties. Over-tightening can cause damage to cables or conduits, while under-tightening may not secure them adequately. It's essential to use the right tools, such as tensioning tools, to achieve the appropriate tightness without compromising the integrity of the cable or the tie itself. Furthermore, protective gloves should be worn to prevent cuts and abrasions that can occur from the sharp edges of stainless cable ties. By following these safety considerations, users can effectively and safely employ stainless cable ties in their applications.

Related Posts

-

Why Releasable Cable Ties Are a Game Changer for Your Organization

-

How to Choose the Right Plastic Ties for Maximum Strength and Durability

-

Exploring the Impact of Zip Tie Tool Innovations at the 2025 China 138th Export Commodities Fair

-

Exploring the Future of Bulk Zip Ties at the 2025 China Import and Export Fair

-

Innovative Zip Tie Tool Solutions Unveiled at the 2025 China Import and Export Fair

-

7 Facts About Plastic Ties That Will Change Your Perspective on Their Durability and Versatility