How to Choose the Best Large Zip Ties for Your Projects and Needs

Choosing the right large zip ties can make a significant difference in the efficiency and success of your projects. With a vast array of options available in the market, it's essential to understand the features and specifications that will best suit your needs. According to John Matthews, a leading expert in the fastening industry, "Selecting the appropriate large zip ties ensures not only the effectiveness of your tasks but also enhances safety and durability." His insights emphasize the importance of quality and suitability in achieving optimal results.

When evaluating large zip ties, consider factors such as tensile strength, material composition, and size. These elements play a crucial role in determining which ties will withstand the demands of your projects, whether you are organizing cables, securing tools, or performing DIY tasks. By paying attention to these details, you can ensure that you are making a well-informed decision that meets both your project's requirements and your personal standards for performance.

Understanding your specific needs is the first step towards finding the best large zip ties. Whether you're a professional looking for reliable solutions or a hobbyist seeking to streamline your projects, the right large zip ties can provide the support and stability needed to achieve your goals. As you navigate through the various choices, keep in mind expert advice and focus on what will truly work for you.

Introduction to Large Zip Ties: Uses and Benefits

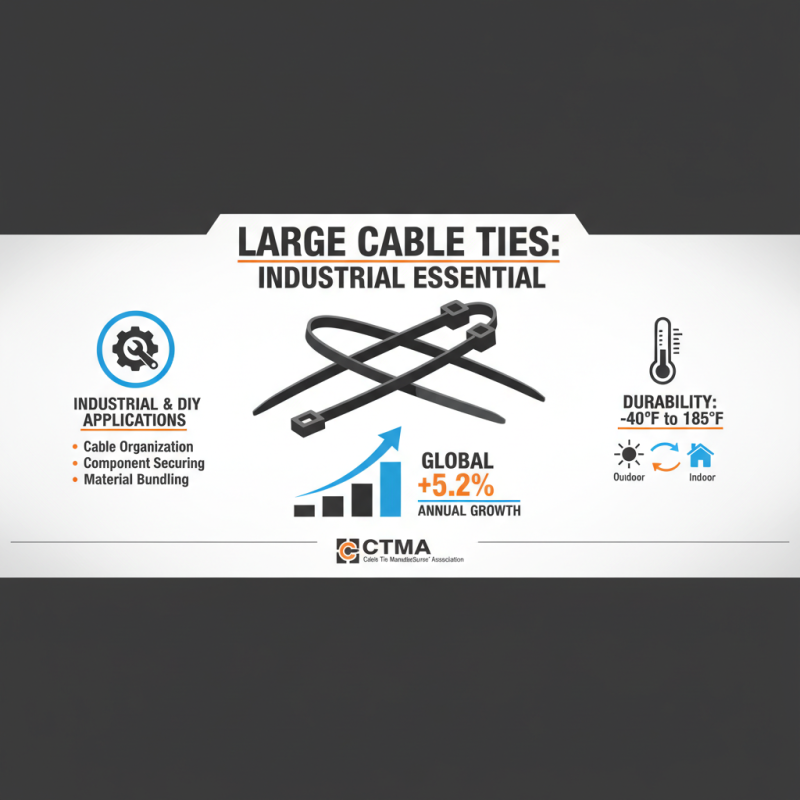

Large zip ties, also known as cable ties, have become essential tools in various industries due to their versatility and strength. They are widely used for organizing cables, securing components, and even bundling materials together. According to a recent report from the Cable Tie Manufacturer’s Association, the demand for zip ties is expected to grow by 5.2% annually, which highlights their importance in both industrial and DIY projects. Their durable design enables them to withstand temperatures ranging from -40°F to 185°F, making them suitable for outdoor and indoor use alike.

In addition to their durability, large zip ties offer benefits such as ease of use and cost-effectiveness. With tensile strength ratings often exceeding 175 pounds, they provide a reliable solution for heavy-duty tasks. Reports indicate that nearly 70% of professionals in construction and electrical fields rely on zip ties for their efficiency in securing items quickly and effectively. These ties come in various sizes and materials, ensuring that there is an option fit for any project—whether it’s for managing electrical cords or building intricate frameworks. Ultimately, large zip ties are not just a handy tool, but a fundamental component across multiple sectors.

Factors to Consider When Choosing Large Zip Ties

When choosing the best large zip ties for your projects, several key factors must be considered to ensure that you meet your specific needs. First and foremost, the material from which the zip ties are made is critical. Many large zip ties are crafted from nylon, known for its durability and resistance to various environmental factors. According to a report by the Plastics Industry Association, nylon zip ties can withstand temperatures ranging from -40°F to 185°F, making them suitable for both indoor and outdoor applications. If your project involves exposure to extreme UV rays or harsh chemicals, selecting zip ties with added UV stabilization or made from stainless steel can enhance longevity and performance.

Another essential factor to consider is the tensile strength of the zip ties. Tensile strength indicates the maximum load the zip tie can handle before breaking. Industry standards suggest that zip ties with a tensile strength of at least 50 pounds are ideal for heavy-duty applications, such as securing large bundles of cables or tying down equipment. A survey conducted by the International Organization for Standardization found that using zip ties with appropriate tensile strength significantly reduces the likelihood of failure during critical operations. Therefore, evaluating the weight and tension requirements of your specific application is vital in selecting the right large zip ties for optimal performance and safety.

Comparing Materials: Nylon, Plastic, and Other Options

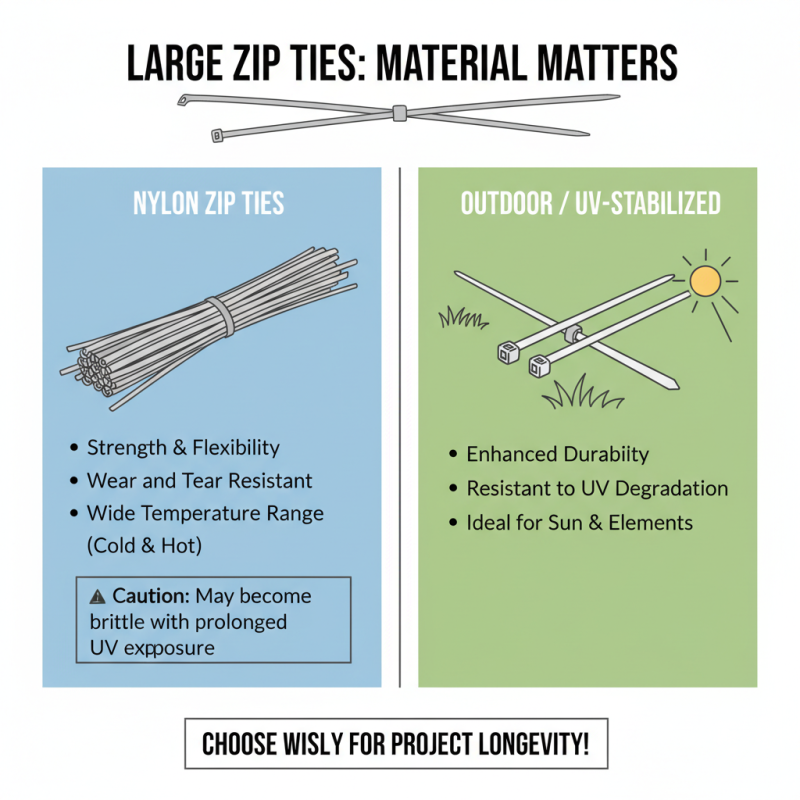

When it comes to selecting large zip ties for various projects, the material plays a critical role in determining their effectiveness and durability. The most common material used for zip ties is nylon, renowned for its strength and flexibility. Nylon ties are typically resistant to wear and tear, making them suitable for outdoor applications where exposure to the elements can lead to degradation. Their ability to withstand a wide temperature range also makes them ideal for both cold and hot environments. However, users should be aware that nylon may become brittle over time when exposed to UV light, so if your projects involve prolonged outdoor use, considering UV-stabilized or weather-resistant options is crucial.

Plastic zip ties present another alternative, often favored for lighter-duty applications. They are generally less expensive than nylon ties and can be sufficient for indoor use or projects that do not require heavy loads. The variety of colors available in plastic ties can also serve aesthetic or organizational purposes in crafts or home improvement projects. Additionally, there are specialty ties made from materials such as stainless steel, which offer exceptional strength and resistance to corrosion, making them perfect for industrial applications or situations where extreme conditions are expected. By understanding the strengths and limitations of various materials, you can make a more informed choice based on your specific project needs.

Understanding Sizes and Strength Ratings of Zip Ties

When selecting the best large zip ties for various projects, understanding their sizes and strength ratings is crucial. Zip ties, often used for cable management, bundling items, and securing materials, come in a range of lengths and widths. The size you choose will depend on the specific application. Longer ties, typically ranging from 14 to 36 inches, can accommodate larger bundles, while shorter ones are more suited for minor tasks. Additionally, the width of the tie can influence its holding capacity; wider ties generally provide greater strength.

In terms of strength ratings, zip ties are categorized by their tensile strength, which indicates the maximum load they can handle before breaking. This rating is usually expressed in pounds and varies significantly among different models. For heavier-duty applications, such as securing outdoor equipment or industrial items, opt for ties that have higher tensile strength ratings. It’s essential to match the tie's strength with the demands of your project to ensure safety and efficiency. By considering both size and strength, you can effectively choose the right large zip ties that will meet your specific project needs.

How to Choose the Best Large Zip Ties for Your Projects and Needs

| Size (Length x Width) | Weight Capacity (lbs) | Material Type | UV Resistant | Temperature Resistance (°F) |

|---|---|---|---|---|

| 14" x 0.19" | 50 | Nylon 6/6 | Yes | 185 |

| 18" x 0.30" | 75 | Polypropylene | Yes | 200 |

| 24" x 0.38" | 120 | Nylon 6/6 | Yes | 185 |

| 30" x 0.50" | 150 | Nylon 6/10 | Yes | 200 |

| 36" x 0.50" | 175 | UV Stabilized Nylon | Yes | 220 |

Recommended Brands and Types for Specific Projects

When selecting large zip ties for various projects, it's essential to consider the specific requirements of each task. For outdoor applications, look for heavy-duty zip ties made from UV-resistant materials to withstand sun exposure and harsh weather conditions. These ties are perfect for securing garden items, temporary structures, or outdoor electrical wiring. In contrast, if your project involves delicate components or sensitive electronics, opt for nylon zip ties with a lower tensile strength, ensuring they won't damage your equipment during installation.

For projects that require exceptional durability, such as industrial applications or construction, consider larger zip ties with reinforced designs. These can accommodate heavier loads and are resistant to moisture and extreme temperatures, making them suitable for securing cables, pipes, or other robust materials. Additionally, if you're working in areas where temperature fluctuations are a concern, silicone rubber-coated zip ties provide added insulation and protection against thermal stress, thus extending the life of your installations.

Comparison of Large Zip Tie Strength for Different Projects

Related Posts

-

Ultimate Guide to Heavy Duty Zip Ties Tips for Maximum Strength and Durability

-

The Ultimate Guide to Using Long Zip Ties for Home Organization and DIY Projects

-

10 Best Steel Zip Ties for Maximum Durability and Versatility in Securing Cables

-

How to Choose the Right Plastic Ties for Maximum Strength and Durability

-

Mastering the Versatility of Nylon Cable Ties: Innovative Uses You Never Knew Existed

-

The Ultimate Guide to Choosing the Best Industrial Zip Ties for Your Projects