How to Choose the Best Stainless Cable Ties for Your Projects

In the realm of industrial and commercial applications, selecting the appropriate fastening solution can significantly influence project outcomes. Among these solutions, stainless cable ties have gained immense popularity due to their durability, resistance to corrosion, and versatility. According to a recent market report by Research and Markets, the global demand for stainless cable ties is projected to grow at a CAGR of 5.2% from 2023 to 2030, driven by advancements in construction and telecommunications sectors. This statistic underscores the importance of making informed choices when it comes to these essential tools.

Experts in the field emphasize that understanding the specific requirements of your projects is crucial to selecting the most suitable stainless cable ties. John Smith, a renowned specialist in fastening technologies, noted, “Choosing the right type of stainless cable ties not only ensures the integrity of your installations but also enhances the overall efficiency and safety of your projects.” With the diverse range of stainless cable ties available in the market, such as different widths, lengths, and locking mechanisms, it is imperative to assess factors including load-bearing capacity, environmental conditions, and application types to achieve optimal results.

This guide aims to provide insights and considerations that will aid in making an informed decision when selecting stainless cable ties for your next project.

Understanding the Different Types of Stainless Cable Ties Available

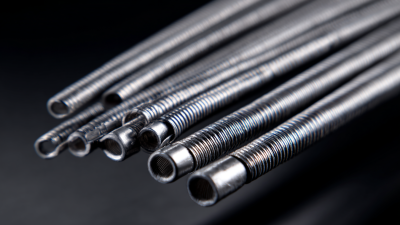

When it comes to selecting stainless cable ties for your projects, understanding the different types available is crucial. Stainless steel cable ties are designed for various applications, each suited to specific needs. For instance, type 201 stainless steel ties are often used in environments where corrosion resistance is important, making them ideal for indoor and moderate outdoor conditions. On the other hand, type 316 stainless steel ties offer superior resistance to harsh environments, including exposure to saltwater and chemicals, making them perfect for marine and industrial applications.

In addition to material types, flexibility and size are also key factors to consider. Some stainless cable ties feature a locking mechanism that enables easy installation and removal, while others are fixed, providing a more permanent solution. Sizes range from small ties suitable for bundling lightweight items to larger ties designed to secure heavy-duty cables. By identifying the specific requirements of your project, such as environmental conditions and load capacity, you can choose the most appropriate stainless cable ties that ensure durability and effectiveness.

Evaluating the Strength and Durability of Stainless Cable Ties

When selecting stainless cable ties for your projects, evaluating their strength and durability is crucial. Stainless steel is renowned for its resistance to corrosion, making it an ideal choice for outdoor and industrial applications. However, not all stainless cable ties are created equal. It's essential to assess the specific grade of stainless steel used in the ties, as some grades offer better tensile strength and resistance to harsh environmental conditions. For instance, ties made from 316-grade stainless steel are particularly well-suited for marine environments due to their superior resistance to saltwater corrosion.

In addition to material grade, consider the design and construction of the cable ties. Features such as thickness, locking mechanism, and width can significantly influence their overall performance. Thicker ties generally provide enhanced strength, while a robust locking mechanism ensures that the tie remains secure under tension. Furthermore, wide cable ties distribute pressure more evenly, minimizing the risk of failure. By carefully evaluating these factors, you can select the best stainless cable ties that will withstand the demands of your projects, ensuring reliability and longevity.

Strength and Durability of Stainless Cable Ties

This chart displays the tensile strength of various stainless cable ties based on their rated strengths. The data indicates how actual tensile strength compares to the rated strength, helping you choose the best option for your projects.

Assessing Temperature and Environmental Resistance of Cable Ties

When selecting stainless cable ties for your projects, it’s essential to assess their temperature and environmental resistance. This consideration is particularly important in contexts where cable ties are exposed to harsh conditions, such as extreme temperatures, humidity, and exposure to chemicals. For instance, in regions like California, where cable management materials are tested under intense environmental conditions, choosing cable ties that can withstand such factors ensures durability and reliability in their application.

Additionally, the environmental impact of cable ties, especially in industries like food packaging, highlights the need for mindful selection. Recent efforts in Indonesia aim to increase awareness of the plastic waste generated by these products, advocating for alternatives that minimize ecological footprints. Choosing the right stainless cable ties not only contributes to project efficiency but also aligns with sustainability goals by reducing reliance on plastic-based options. This dual focus on performance and environmental responsibility can guide your selection process effectively.

Determining the Correct Size and Length for Your Cable Ties

When determining the correct size and length for stainless cable ties, it's essential to consider the specific requirements of your project. According to a report by MarketsandMarkets, the global market for cable ties is projected to grow significantly, driven by advancements in material technology and increased demand in various industries such as automotive and electronics. The right size of cable tie not only ensures a secure hold but also avoids unnecessary strain on the cable or item being tied, which can lead to damage over time.

Selecting the appropriate length is equally crucial. As a general guideline, the length of the cable tie should be at least 4 inches longer than the diameter of the bundle being secured. This ensures that there is enough tail length for optimal tightening while maintaining a neat appearance. Industry studies indicate that a properly sized cable tie can enhance performance by up to 30%, reducing the need for replacements and maintenance. Using the right size and length not only improves your project's efficiency but also prolongs the lifespan of the tied components, making it a smart choice for both DIY enthusiasts and professionals alike.

Exploring the Applications and Uses of Stainless Cable Ties in Projects

Stainless cable ties have become integral to various projects, thanks to their unmatched durability and resistance to environmental factors. As the global cable cleats market is expected to grow significantly, from $331.42 million in 2024 to an impressive $666.78 million by 2032, with a Compound Annual Growth Rate (CAGR) of 9.13%, the demand for robust solutions like stainless steel cable ties is on the rise. These ties provide a reliable method for securing cables in settings where standard plastic alternatives may fail, such as in solar energy installations and outdoor applications where weather resistance is critical.

Applications of stainless cable ties are widespread across different industries. For instance, sectors that require stringent hygiene standards, such as cleanrooms, benefit from antimicrobial and metal-detectable cable ties. This is especially important in environments where cleanliness is paramount. Moreover, innovative solutions like permanent cable ties are being introduced specifically for solar projects, which demand longevity and performance under harsh conditions. By choosing stainless cable ties, project managers can ensure they have a solution that not only meets their immediate needs but also contributes to the long-term integrity of their installations.

Related Posts

-

15 Essential Tips for Using Stainless Cable Ties Effectively

-

Innovative Uses of Stainless Steel Zip Ties for Home and Garden Projects

-

Exploring the Strength of Stainless Steel Zip Ties: The Ultimate Choice for Industrial Applications

-

Explore the Best Stainless Zip Ties for 2025: Top Picks & Benefits

-

2025 Guide: How to Choose the Best Bulk Zip Ties for Your Projects

-

10 Best Cable Ties in the UK for All Your Wiring Needs